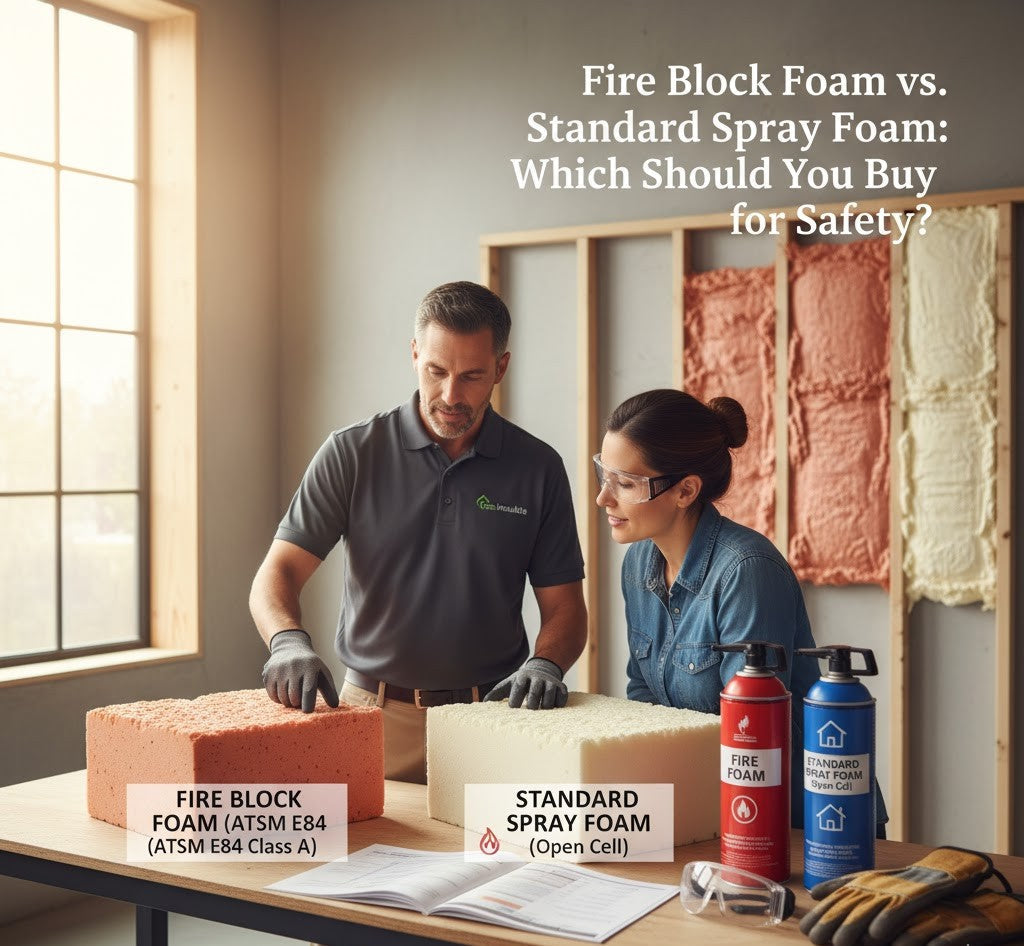

When improving your home’s insulation, the choice between fire block foam vs standard spray foam is more than a question of comfort it’s about safety, code compliance, and long-term performance. Fire block foam is specifically engineered to provide insulation and flame-resistant sealing, while standard spray foam focuses primarily on thermal efficiency. Understanding the differences helps you select the right material for each part of your project.

Fire block foam is increasingly preferred by DIY homeowners, builders, and light commercial fabricators who prioritize safety and durability. It combines fire-resistant spray foam insulation with strong air-sealing and soundproofing properties, ensuring that walls, attics, and floor cavities stay both energy-efficient and protected. In contrast, standard spray foams may insulate well but often require extra fire protection to meet modern building codes.

Key Takeaways

-

Fire block foam is a fire-resistant spray foam insulation that meets UL and ASTM fire safety standards.

-

It combines air sealing with fire protection, improving both safety and efficiency.

-

The foam suits attics, wall gaps, crawl spaces, and electrical penetrations.

-

It already meets building code requirements for spray foam, eliminating extra coatings.

-

Provides long-term performance for DIY homeowners and professional contractors alike.

1. Fire Block Foam Provides Verified Fire Resistance

The most important distinction between the two foams is how they behave under heat. Standard spray foam can ignite quickly and contribute to flame spread, while fire block foam is formulated to resist ignition and slow down heat transfer.

Safety-Rated Protection

High-quality fire block foams carry UL fire-rated foam sealant certifications and meet ASTM E84 and UL 94 testing standards. These ratings confirm that the material provides a Class A flame-spread rating, meaning it resists fire propagation within wall cavities, attics, or floor penetrations.

Fire block foam is typically used around:

-

Framing joints and wall gaps

-

Electrical and plumbing penetrations

-

HVAC and vent openings

-

Recessed lights and outlet boxes

The fire block foam kit from VB Insulation contains a closed-cell formula that self-extinguishes when exposed to flames. Instead of burning, it forms a protective char layer that prevents heat from traveling through concealed spaces.

Fire Block Foam Safety Rating

Because it’s a fire retardant foam insulation, fire block foam gives homeowners valuable extra time during emergencies. Its UL 94 rating demonstrates that it will not support combustion once the ignition source is removed, making it one of the safest insulation choices for residential and small commercial applications.

2. Meets Building Code Requirements Automatically

Meeting building code requirements for spray foam is essential for any project, and this is where fire block foam clearly outperforms standard spray foams.

Code-Compliant by Design

Most residential codes require fire-blocking materials in concealed wall and ceiling spaces. Standard foams often need an additional fire-resistant coating to pass inspection, while fire block foam already includes those properties. Using it ensures automatic compliance and simplifies the approval process.

For areas like top plates, floor junctions, and electrical chases, fire block foam not only insulates but also provides the fire separation required by inspectors.

Ideal for DIY and Light Commercial Use

Homeowners can install fire block foam without worrying about additional treatments. It provides dependable protection and insulation in one step, making it perfect for both DIY projects and small-scale commercial retrofits.

3. Delivers Superior Air Sealing and Energy Efficiency

Fire block foam’s advantages extend far beyond safety. As a closed-cell spray foam, it offers excellent air sealing performance that directly improves energy efficiency.

Airtight Performance

Even small cracks and penetrations can lead to energy loss. Fire block foam expands on contact, filling voids and preventing airflow between conditioned and unconditioned spaces. This reduces heating and cooling costs while maintaining consistent indoor comfort.

Compared to open-cell foams, closed-cell formulations provide stronger vapor resistance, reducing condensation and mold risks. This makes them ideal for use in basements, crawl spaces, and attic floors.

More detailed comparisons of foam performance and R-values can be found in VB Insulation’s spray foam guide, which helps homeowners choose the right product based on budget and building type.

Long-Term Savings

The foam’s dense structure delivers a higher R-value per inch than many standard spray foams. Over time, improved insulation performance leads to reduced energy bills and less strain on HVAC systems, adding measurable value to your home.

4. Enhances Soundproofing and Structural Strength

Another key difference between the two foams lies in the added performance benefits. Fire block foam doesn’t just seal it reinforces and insulates.

Multipurpose Protection

In addition to thermal resistance, fire block foam improves soundproofing by blocking air pathways where noise travels. It creates a quiet, comfortable environment while maintaining fire protection.

Because of its closed-cell composition, the foam also strengthens wall assemblies by bonding tightly to wood, concrete, and metal. Once cured, it provides rigidity that helps resist movement, vibration, and impact.

VB Insulation explains the heat behavior of closed-cell materials in its article on foam flammability, which highlights why dense foams maintain their structure under extreme temperatures.

Durable and Moisture-Resistant

Closed-cell foams are inherently resistant to moisture absorption, making them effective barriers against humidity. This prevents water vapor from damaging insulation layers and framing materials an advantage standard spray foams can’t always guarantee.

5. Simple for DIY Use but Reliable for Professionals

Ease of use is another reason many homeowners choose fire block foam over standard options. It provides professional-grade results with minimal equipment or training.

Straightforward Application

The single-component system allows users to apply the foam with precision:

-

Consistent spray pattern for accuracy

-

Controlled expansion to minimize waste

-

Fast curing for quick project completion

-

Coverage of up to 20 sq ft per canister

Fire block foam is ideal for sealing wall penetrations, pipe entries, and small cavities that standard foams may miss.

Safe Placement

Although versatile, not every surface is suitable for spray foam. It should not be applied near high-heat appliances or in areas with persistent moisture exposure. VB Insulation’s article on foam application areas explains proper installation zones to ensure both performance and safety.

Professional Results for Contractors

Because of its consistency and adhesion, many contractors use the same formulation for commercial building insulation foam. It meets fire-blocking codes while providing excellent thermal and acoustic sealing ideal for renovations and new construction alike.

FAQs

What is the difference between fire block foam and standard spray foam?

Fire block foam contains fire retardant foam insulation additives that slow flame spread. Standard spray foam insulates effectively but lacks built-in fire resistance.

Is fire block foam fireproof or just fire-resistant?

It’s fire-resistant, not fireproof. The foam resists ignition and reduces heat transfer, helping to contain fires within concealed areas.

When should I use fire block foam instead of regular spray foam?

Use it in spaces where fire safety codes require flame-blocking materials, such as around outlets, plumbing lines, or between floor levels.

Does fire block foam provide the same insulation as standard spray foam?

Yes. It provides comparable R-values while adding superior safety and structural reinforcement.

Can I use fire block foam in attics, basements, or near electrical boxes?

Yes. It’s approved for attics, basements, and crawl spaces and ideal for sealing electrical or plumbing penetrations.

How do I verify that my project meets fire safety codes?

Check for UL-rated or ASTM E84-tested products. These indicate compliance with national fire standards.

Is fire block foam worth the extra cost?

Yes. Its combination of fire resistance, air sealing, and code compliance delivers long-term safety and energy savings.

Which brands are most trusted for spray foam insulation?

VB Insulation is recognized for producing professional-grade spray foam products that balance safety, performance, and value.