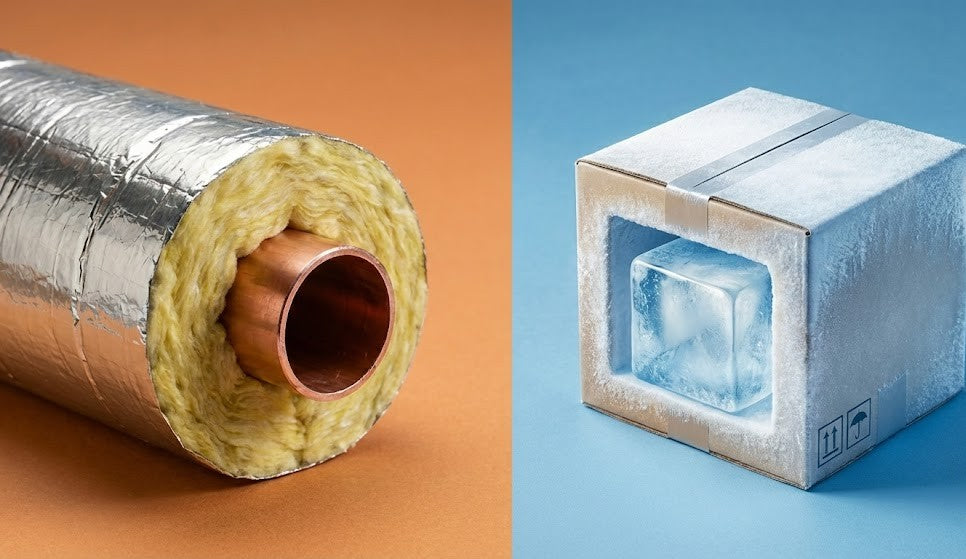

Insulation is often treated as a single solution, but in reality, different insulation materials are designed for very different conditions. One of the most common areas of confusion for homeowners, DIY builders, and light commercial users is understanding the difference between hot insulation materials and cold insulation materials.

Both types slow heat transfer, but they do so in different ways and for different reasons. Choosing the wrong insulation can lead to higher energy bills, moisture problems, and reduced comfort. This guide explains the difference in simple, practical terms so you can decide what works best for your specific project.

Key Takeaways: Hot vs Cold Insulation Materials

- Hot insulation materials reduce heat loss from hot surfaces

- Cold insulation materials prevent heat gain and condensation

- Moisture control is more critical in cold insulation systems

- Climate and application determine the right insulation choice

- Some insulation types, like spray foam, can work in both conditions

Understanding Insulation and Heat Transfer

Heat naturally moves from warm areas to cooler ones through conduction, convection, and radiation. Insulation slows this movement by creating resistance to heat flow, helping maintain stable indoor temperatures and improving energy efficiency.

While all insulation resists heat movement, hot and cold insulation materials are designed for different temperature ranges and operating conditions, which plays a major role when evaluating the best insulation for a home or light commercial space.

Insulation helps control:

- Heat escaping from hot systems

- Heat entering cooled spaces

- Air leakage through gaps and joints

- Moisture movement that leads to condensation

What Are Hot Insulation Materials?

Hot insulation materials are designed to retain heat and reduce heat loss from surfaces operating at elevated temperatures. These materials are commonly used around heating systems, hot pipes, and mechanical equipment.

They improve system efficiency while also protecting nearby materials and people from excessive surface heat.

Primary Purpose of Hot Insulation

The main purpose of hot insulation is energy efficiency and safety.

Hot insulation materials help by:

- Reducing heat loss from hot systems

- Improving equipment performance

- Lowering energy consumption

- Reducing burn and fire risks

The U.S. Department of Energy notes that insulating hot water pipes can significantly reduce standby heat loss and improve overall system efficiency.

Common Types of Hot Insulation Materials

Mineral Wool Insulation

Mineral wool insulation is widely used in high-temperature applications because it can withstand heat and resist fire. It is dense, durable, and performs well in demanding environments.

This material is commonly used in boiler rooms, mechanical spaces, and fire-rated assemblies, including applications involving flue systems where prolonged thermal exposure is a concern.

Fiberglass Insulation

Fiberglass insulation is a cost-effective option for moderate-temperature applications. It is lightweight, widely available, and easy to install when handled correctly.

Common fiberglass uses include:

- HVAC ductwork

- Water heaters

- Utility rooms

- Residential heating systems

Fiberglass must remain dry to maintain long-term performance.

Where Hot Insulation Is Typically Used

Hot insulation materials are installed wherever heat retention and protection are priorities.

Typical hot insulation applications include:

- Boilers and furnaces

- Hot water and steam pipes

- HVAC duct systems

- Mechanical and utility rooms

- Industrial heating equipment

Proper installation reduces energy loss and helps extend equipment lifespan.

What Are Cold Insulation Materials?

Cold insulation materials are designed to prevent heat gain and control condensation on cold surfaces. These materials are essential for maintaining temperature stability and preventing moisture-related damage.

Cold insulation is commonly used in refrigeration systems, basements, cold storage areas, and exterior walls in colder climates.

Primary Purpose of Cold Insulation

The primary goal of cold insulation is to manage temperature and moisture at the same time.

Cold insulation helps by:

- Blocking external heat from entering cooled spaces

- Preventing condensation buildup

- Reducing mold and corrosion risk

- Protecting building materials

The U.S. Environmental Protection Agency highlights moisture control as a key factor in building durability and indoor air quality.

Common Types of Cold Insulation Materials

Closed-Cell Spray Foam Insulation

Closed-cell spray foam is one of the most effective cold insulation materials available. It combines high R-value performance with air sealing and moisture resistance in a single application.

It is commonly used in basements, exterior walls, refrigeration lines, and cold storage spaces.

Rigid Foam Board Insulation

Rigid foam board insulation provides consistent thermal resistance and is easy to install on flat surfaces.

Benefits of foam board insulation include:

- Stable R-value over time

- Lightweight and durable structure

- Moisture resistance

- Long service life

Where Cold Insulation Is Commonly Used

Cold insulation materials are installed where temperature control and moisture prevention are critical.

Common cold insulation applications include:

- Refrigeration and freezer systems

- Cold storage rooms

- Exterior walls in cold climates

- Basements and crawl spaces, where effective basement insulation helps control moisture and heat loss

- HVAC cooling lines

Hot vs Cold Insulation Comparison

|

Feature |

Hot Insulation Materials |

Cold Insulation Materials |

|

Primary Function |

Reduce heat loss |

Prevent heat gain |

|

Operating Temperature |

High-temperature systems |

Low-temperature systems |

|

Moisture Resistance |

Limited |

High priority |

|

Typical Materials |

Mineral wool, fiberglass |

Spray foam, foam board |

|

Vapor Barrier |

Usually not required |

Often required |

|

Common Uses |

Boilers, hot pipes, HVAC |

Refrigeration, basements |

Can One Insulation Material Work for Both Hot and Cold Conditions?

Yes. Some insulation materials perform effectively across a wide range of temperatures.

Why Spray Foam Works in Both Applications

Closed-cell spray foam offers:

- High thermal resistance

- Strong air sealing

- Excellent moisture control

- Reliable performance in mixed climates

ASHRAE emphasizes that air sealing is one of the most effective ways to improve insulation performance, which is why spray foam efficiency is often higher than traditional insulation materials.

Climate and Budget Considerations

Climate plays a major role in insulation performance. Cold climates require materials that reduce heat loss and block moisture. Warm climates focus on limiting heat gain and improving comfort.

From a budget perspective, fiberglass and mineral wool usually have lower upfront costs. Spray foam insulation costs more initially but can deliver long-term savings, which often factors into the overall cost of insulation decisions.

Installation Tips for DIY and Light Commercial Users

DIY homeowners should focus on insulation materials that are easy to install and forgiving during application, especially when taking a DIY approach to spray foam insulation. Starting with the right material reduces mistakes and makes the installation process more manageable.

Surface preparation also plays a major role in performance. A clean, dry surface helps insulation bond properly and perform as intended over time. It also reduces the risk of uneven coverage, wasted material, and small gaps that allow air leakage.

For cold insulation projects, moisture control becomes even more important. Damp surfaces can interfere with adhesion and increase the likelihood of condensation problems later on. In light commercial spaces, following consistent preparation steps helps maintain uniform results across larger areas such as mechanical rooms and utility spaces.

Practical setup checklist:

- Remove dust, loose debris, and oils from the surface

- Confirm the area is dry before applying insulation

- Seal obvious gaps first so insulation thickness stays consistent

- Plan access so you’re not stepping over freshly applied material

- Keep tools, lighting, and PPE ready before you start

Why Choose VB Insulation?

Choosing the right insulation is easier when you have dependable products and clear guidance to support your decision. VB Insulation is built around practical solutions that help homeowners, DIYers, and light commercial users achieve reliable results without unnecessary complexity.

What sets VB Insulation apart:

- A complete collection of spray foam insulation kits, accessories, and application tools

- Their Product options designed for residential and light commercial projects

- Energy-efficient solutions that help improve comfort and reduce long-term costs

- Insulation products made for straightforward installation and lasting performance

Contact with their support team to get help with product selection, coverage questions, and application guidance

Whether you are planning a small DIY upgrade or a larger insulation project, having access to the right products and a responsive support team helps ensure your project is completed with confidence.

FAQs: Hot and Cold Insulation Materials

What is the main difference between hot and cold insulation materials?

The difference is their function. Hot insulation reduces heat loss from hot surfaces, while cold insulation prevents heat gain and condensation.

Which insulation is best for cold climates?

Closed-cell spray foam performs well in cold climates due to its high R-value and moisture resistance.

Can spray foam be used near hot systems?

Yes. Spray foam is suitable for moderate-temperature applications such as HVAC systems and mechanical rooms.

Is cold insulation only used for refrigeration?

No. Cold insulation is also used in basements, crawl spaces, and exterior walls to manage temperature and moisture.