Is Closed Cell Foam Hard or Soft? Find Out Here

Many people wonder if closed-cell foam is hard or soft. This foam is used in many ways, including insulation and building materials, so knowing its properties is key. In this guide, we'll look at what makes closed-cell foam hard or soft, its special features, and how it compares to open-cell foam.

Key Takeaways

- Closed-cell foam can range from soft to rigid depending on its density and manufacturing process.

- Factors like foam density, compression strength, and formulation affect the hardness of closed-cell foam.

- Closed-cell foam offers superior moisture resistance, insulation properties, and structural support compared to open-cell foam.

- Closed-cell foam can be used for various applications, including insulation, construction, and specialty products.

- Determining the right type of closed-cell foam for your needs requires understanding its specific properties and performance characteristics.

Understanding Closed Cell Foam

Closed-cell foam is a rigid insulation material that outperforms open-cell foam. Its closed-cell design, unlike open-cell foam's airy structure, boosts insulation, fights moisture, and adds strength.

What is Closed Cell Foam?

Closed-cell foam is made from synthetic materials like polyurethane or polyisocyanurate. Its tightly packed, non-porous structure traps air or gas, making it a top-notch insulation barrier. It's also durable and water-resistant, protecting against moisture.

Closed Cell vs. Open Cell Foam: Key Differences

- Closed-cell foam is denser and more compact than open-cell foam's airy structure.

- It insulates better, with a higher R-value than open-cell foam.

- It's more moisture-resistant and durable, which is ideal for water protection.

- Open-cell foam is softer and more flexible, while closed-cell foam is rigid and strong.

Closed-cell foam is a top choice for many uses, from insulation to construction and packaging. Knowing the differences between closed and open-cell foam helps you choose the right material for your needs.

Read More: Closed Cell Spray Foam vs Open Cell Spray Foam

Factors Affecting Closed Cell Foam Hardness

The hardness of closed-cell foam comes from its density, compression strength, and how it's made. Knowing these factors helps determine how firm or soft the foam is. This is important for different uses of closed-cell foam.

Foam Density and Compression Strength

The density of closed-cell foam greatly affects its hardness. Thicker foams are usually firmer and stiffer, while thinner foams are softer and more bendable.

The foam's ability to handle pressure also matters. Denser foams can take more pressure without getting squished. So, they are harder and less squishy than thinner foams.

Manufacturing Process and Formulation

How closed-cell foam is made also changes its hardness. The materials used, the blowing agent, and how it's cured all play a part. These steps can make the foam more or less rigid and firm.

By controlling these steps, foam makers can adjust the foam's density and resilience. This makes the foam better for different uses.

Understanding these factors helps both foam makers and users. They can choose the right foam for their needs. This applies to insulation, building, or other uses where foam's hardness and squishiness matter.

Is Closed Cell Foam Hard or Soft? Find Out Here.

Closed-cell foam can be either hard or soft, depending on its type and use. It's usually a stiff, dense material that supports structures well, but some types can be flexible and easy to bend.

The firmness of closed-cell foam depends on its density and compression strength. Foams with higher density are harder and stiffer, while those with lower density are softer and more compressible. How the foam is made also affects its resilience and durability.

Closed-cell foam is great for keeping things in shape, such as in building, packaging, and moving. It's also flexible enough to make different hard and soft products.

Are you looking for a hard or soft closed-cell foam? Knowing its hardness and softness helps you choose the right one. Consider density, compression strength, and how it's made to pick the best foam for your project.

Closed Cell Foam Applications

Closed-cell foam is a versatile material that can be used in many ways. It's known for its rigidity, moisture resistance, and thermal insulation. It's mainly used for energy-efficient insulation and structural support in construction.

Insulation and Energy Efficiency

Closed-cell foam is great for insulation because it traps air and moisture. It helps buildings, homes, and industrial places use less energy, keeping the inside warm or cool and cutting down on energy bills.

Construction and Structural Support

Closed-cell foam adds insulation and strength to construction. Its rigidity and strength are perfect for walls, roofs, and more. It keeps buildings stable and strong, from houses to big buildings.

Closed-cell foam is key to better energy use and building strength. Its flexibility and effectiveness make it a top pick for many projects.

Read More: What are the applications of closed cell foam?

Closed Cell Foam Properties

Closed-cell foam is a remarkable material with many exceptional properties. It is known for its moisture resistance. Unlike open-cell foam, it doesn't absorb water, making it perfect for places with moisture.

This foam is also very durable. It can handle a lot of pressure, tears, and scratches without losing its shape, making it great for many uses.

Closed-cell foam is also great at blocking sound and keeping temperatures steady. Its closed-cell structure stops sound from passing through, making it a top choice for sound insulation. Plus, its low thermal conductivity helps keep temperatures controlled, saving energy.

Moisture Resistance and Durability

- Closed-cell foam is highly resistant to water absorption, making it ideal for applications where moisture exposure is a concern.

- The closed-cell structure of this foam provides exceptional durability with superior compression, tear, and abrasion resistance.

- Closed cell foam's water-resistant and durable properties make it a versatile choice for a wide range of applications, from construction to industrial uses.

Acoustic and Thermal Performance

- Closed-cell foam's closed-cell structure effectively blocks sound transmission, providing excellent acoustic performance and insulation.

- The low thermal conductivity of closed-cell foam makes it an efficient insulator, helping to maintain temperature control and improve energy efficiency.

- These unique thermal and acoustic properties make closed-cell foam a popular choice for sound and thermal management applications.

Read More: What are the components of closed cell spray foam?

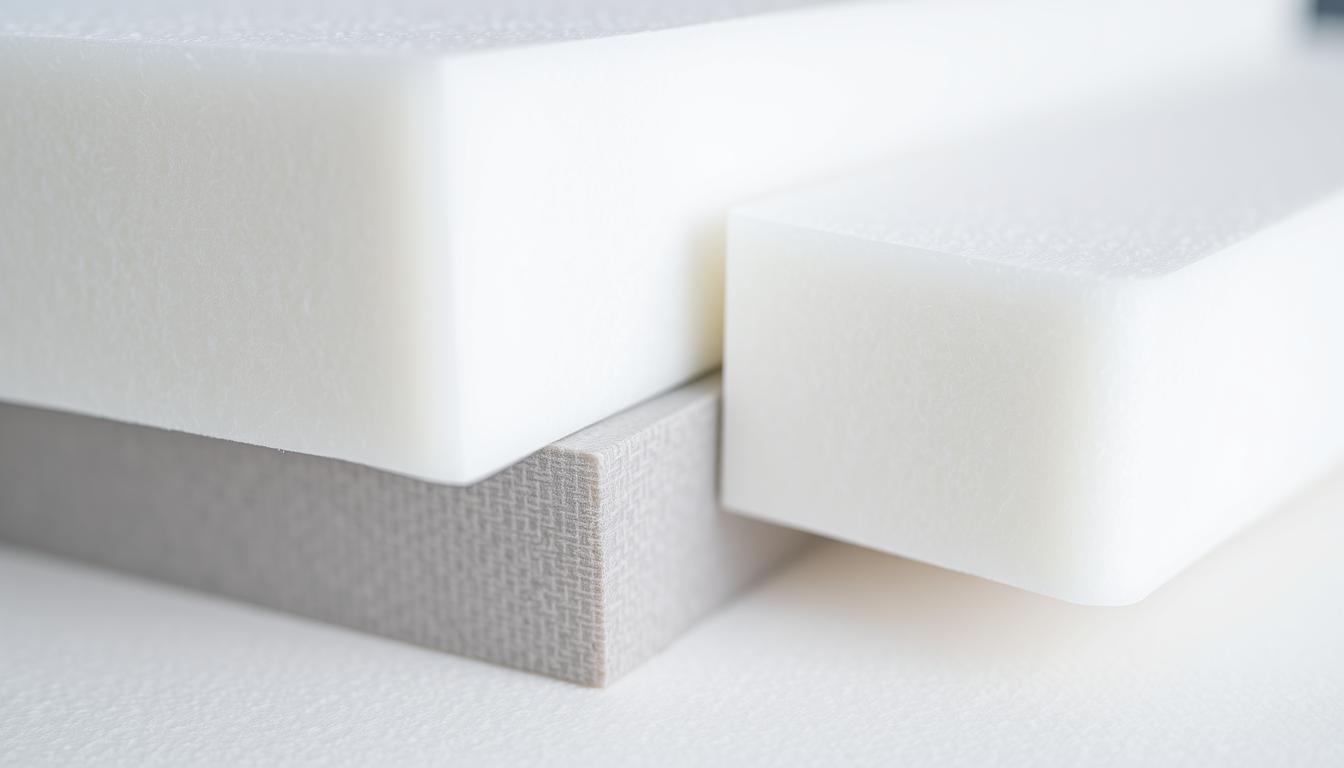

Closed Cell Foam Types and Varieties

Closed-cell foam comes in more types than you might think. It's not just rigid; there are also flexible options. Knowing the different types helps you pick the best one for your needs.

Rigid Closed Cell Foam

Rigid closed-cell foam is the classic, dense version. It's great for insulation, resisting moisture, and holding up well. It's often used in building, industry, and special equipment where strength is key.

Flexible Closed Cell Foam

Flexible closed-cell foam is softer and more pliable. It still offers water resistance and keeps things warm, but it's better for softer needs. It's great for packaging, gaskets, and anything that needs to cushion or seal.

Knowing the options is crucial whether you need rigid or flexible closed-cell foam. The right closed-cell foam types and varieties make a big difference, and the foam's flexibility affects how well it works for your project.

Closed Cell Foam from VB Insulation

VB Insulation is a top maker of closed-cell foam products. They aim to offer innovative solutions for construction, insulation, and industrial needs. They focus on quality, safety, and customer satisfaction, making them a reliable partner for businesses and homeowners.

Quality Products and Services

VB Insulation's closed-cell Spray foam is known for its top-notch performance and lasting durability. It uses the latest methods and formulas to make these products, which offer great insulation, moisture resistance, and support.

Their team works closely with clients to meet high standards in every project. VB Insulation also offers a range of services. This includes custom fabrication, on-site installation, and technical help. They aim to meet every project's unique needs.

If you need insulation for a commercial building, structural support for an industrial facility, or a reliable solution for a home project, VB Insulation can help. They are committed to quality and customer satisfaction. They are ready to assist you in achieving your goals.

How to Determine Foam Hardness

Figuring out if foam is hard or soft is key when picking the right foam for a job. There are many types of foam, each with its own firmness and resilience. Luckily, there are standard ways to check how hard foam is.

Foam Compression Testing

Compression testing is a common method for measuring foam hardness. It involves pushing on the foam with a set amount of force and measuring how much it compresses. The more force needed, the harder the foam.

Foam Resilience Evaluation

Another way to check foam hardness is by looking at its resilience. This means quickly pushing on the foam and then letting it go to see how fast it bounces back. Foams that bounce back quickly are usually harder and more supportive.

Pliability and Softness Assessments

Testing foam's flexibility and softness can also give clues about its hardness. You can do this by bending or squeezing the foam to see how it feels. Softer foams are easier to bend and feel softer to the touch.

By using these different tests, you can understand how hard different foams are. This helps you choose the best foam for your needs.

Closed Cell Foam Advantages and Disadvantages

Closed-cell foam has many benefits and some drawbacks. It's a versatile material that can be useful in various ways. Let's explore the good and bad sides of closed-cell foam to help you decide.

Closed Cell Foam Advantages

Closed-cell foam is great at keeping things warm. Its low thermal conductivity means it holds heat well, making it perfect for insulation in buildings and for keeping equipment warm.

It's also water-resistant and durable. The foam's closed-cell structure prevents water from getting in, which is great for places where water is a problem, like near the sea or in areas that flood.

Closed Cell Foam Disadvantages

Even though closed-cell foam has many benefits, it also has some downsides. It's more expensive than open-cell foam because it takes more to make and costs more to buy.

It could be more flexible. The foam's closed-cell structure makes it stiff, making it hard to use in projects that need to fit into tight spaces.

Choosing between closed-cell foam and open-cell foam depends on your needs. Consider your budget and project needs. This will help you make the best choice for your situation.

Read More: 7 Main Benefits of Closed Cell Spray Foam Insulation

Conclusion

As we wrap up our look at closed-cell foam, it's clear this material is special. It has a mix of qualities that make it great for many uses. It's top-notch for keeping things warm or cool and also strong.

We've examined what makes closed-cell foam hard or soft, its density, and its manufacturing process. We've also seen how it's used in many ways, such as keeping buildings warm and providing support.

If you need something that lasts and keeps moisture out or a strong material for building, closed-cell foam is a top choice. Knowing the closed-cell foam summary, key takeaways, and review helps you use it well.

FAQ

What is closed-cell foam?

Closed-cell foam is a type of insulation made from synthetic materials like polyurethane or polyisocyanurate. Its closed-cell structure gives it better insulation, moisture resistance, and support than open-cell foam.

How does closed-cell foam differ from open-cell foam?

Closed-cell foam has tightly packed, non-porous cells, which make it rigid and resistant to moisture. Open-cell foam, on the other hand, has a more porous, flexible structure.

Is closed-cell foam hard or soft?

Closed-cell foam is usually rigid and high-density and offers great structural support. However, depending on how it's made, some types can be more flexible and pliable.

What factors affect the hardness of closed-cell foam?

Several factors affect closed-cell foam's hardness, including its density, compression strength, and manufacturing process. Higher-density foams are firmer, while lower-density ones are more flexible.

What are the common applications of closed-cell foam?

Closed-cell foam is used for insulation and structural support in construction. Its rigidity, moisture resistance, and thermal insulation make it versatile for many industries.

What are the key properties of closed-cell foam?

Closed-cell foam is known for its moisture resistance, durability, and thermal insulation. It also has high compressive strength and can be effective for sound and thermal conductivity.

What are the different types of closed-cell foam?

Closed-cell foam comes in rigid and flexible types. Rigid foams are firm, while flexible ones are more cushioning. Each type has its uses and characteristics.

How can I determine the hardness of a foam product?

You can measure foam hardness through firmness, compressibility, and resilience tests. Industry standards and testing procedures help evaluate foam hardness, including closed-cell foam.

What are the advantages and disadvantages of using closed-cell foam?

Closed cell foam's main advantages are its insulation, moisture resistance, and support. However, it might be more expensive and harder to install than other foams. It's important to consider these points when choosing a foam for your needs.