Do you want to make your home more energy-efficient and comfortable? Then read this guide on DIY spray foam insulation from VB Insulation. You might first ask, "What makes spray foam insulation the best choice for home projects?"

This guide will show you the numerous benefits of spray foam insulation, discuss the available types, and help you with a DIY project. Spray foam insulation can lower your heating and cooling costs, boost your home's thermal performance, and live sustainably. This guide gives you the information and confidence to do it right.

Key Takeaways

- Discover the remarkable advantages of spray foam insulation for your home.

- Learn about the different types of spray foam and how to choose the right one for your project.

- Gain step-by-step guidance on properly preparing, mixing, and applying spray foam insulation.

- Understand the importance of safety precautions and best practices for a successful DIY installation.

- Explore cost-effective solutions and long-term energy savings with spray foam insulation.

Introduction to Spray Foam Insulation

At VB Insulation, we know how crucial it is to invest in energy-efficient home upgrades. Spray foam insulation is a top choice. It offers great insulation, seals air leaks, and controls moisture. Homeowners choose it to boost their home's comfort and performance.

Benefits of Spray Foam Insulation

This insulation is best known for keeping a home cozy without spending too much energy. Thanks to its high R-values, it's better at insulating than other materials. Plus, it stops moisture, which helps maintain your house's condition and keeps you healthy.

Types of Spray Foam Insulation

VB Insulation offers many spray foam insulation kits to meet various needs. Whether you want something eco-friendly or affordable, we've got you covered. Our options range from open-cell to closed-cell, all aiming to enhance your home's efficiency and comfort.

DIY Spray Foam Insulation: Comprehensive Guide

Welcome to VB Insulation's important tutorial on DIY spray foam insulation. We will guide you through every step, including finding the right materials and equipment and learning how to install the foam properly. By the end, you'll have all the skills needed to finish your home improvement and insulation projects successfully.

Are you aiming to boost your home's energy efficiency, cut down on bills, or make your space cozier? This guide has you covered. You'll explore different insulation materials, learn why weatherization and air sealing are crucial, and explore the lasting environmental impact of your work.

In this guide, we'll walk through every critical step, from getting your project area ready to actually putting on the foam. We'll also highlight safety steps and how to tackle issues, making your DIY home improvement both successful and cost-efficient. Finish reading, and you'll be ready to up your home's thermal performance and moisture control with spray foam insulation.

Preparing for the Insulation Project

Before starting your DIY spray foam insulation project with VB Insulation, you need to know a few things. This will ensure your project goes well. We'll show you the important steps to prepare for your home insulation project.

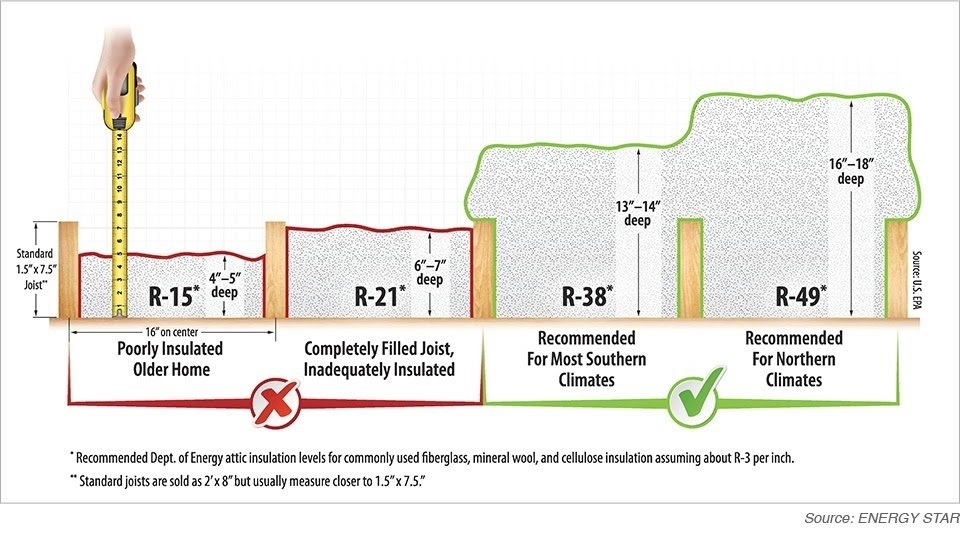

Understanding R-Values and Insulation Requirements

The R-value is key when choosing insulation. It tells you how well insulation can keep heat in or out. Knowing the right R-values for your area and your home helps you choose the best insulation. VB Insulation has a tool to help you pick the perfect R-value and materials for your project.

Choosing the Right Spray Foam Insulation Kit

Choosing the right spray foam insulation kit is very important for a DIY project. VB Insulation has various kits for different budgets and project sizes. When choosing a kit, you must consider its coverage, R-value, and ease of use.

Necessary Tools and Equipment

To prepare, make sure you have all the right tools and equipment. In addition to the spray foam kit, you might also need safety gear, application tools, and other accessories. VB Insulation can tell you exactly what you need for your project.

Step-by-Step Guide to DIY Spray Foam Installation

Embarking on a DIY spray foam insulation project can be rewarding. Just make sure to follow the right steps for success. At VB Insulation, we'll lead you carefully through each part.

Preparing the Surface

First, prepare the surface for spray foam. Clean it well to remove dirt or dust. This helps the foam stick better. The area must be dry and free of moisture.

Mixing the Spray Foam Components

Spray foam insulation needs mixing resin and an activator. Always follow the instructions for mixing them. This is key to getting the best out of your spray foam.

Applying the Spray Foam Insulation

Now, it's time to apply the foam. Use the right techniques to ensure it covers everything evenly. Focusing on corners and small areas is important, as this helps seal your home well.

Safety Precautions and Best Practices

Working with spray foam insulation means safety should come first. Protect yourself and your home. VB Insulation has put together a helpful guide for your DIY project's safety.

Personal Protective Equipment

Having the right gear is crucial. Make sure you're equipped with:

- Chemically resistant gloves to protect your hands from the spray foam components

- Safety goggles to shield your eyes from any overspray or splashes

- A well-fitted respirator or mask to filter out any airborne particles or fumes

- Coveralls or protective clothing to cover your skin and prevent direct contact with the spray foam.

Ventilation and Air Quality

Good ventilation keeps the air clean and safe when using spray foam insulation. Put these steps in action:

- Seal off the work area with plastic sheeting to contain any overspray or fumes.

- Utilize high-powered fans or ventilation systems to circulate fresh air and remove any contaminants continuously.

- Monitor the air quality throughout the installation process and take breaks as needed to maintain a safe working environment.

- Carefully follow the manufacturer's instructions regarding air sealing techniques and moisture control to prevent any potential issues with the building envelope.

By following these rules, your DIY spray foam job will be safe and successful. It will also make your home more energy efficient and better overall.

Troubleshooting Common Issues

A DIY spray foam insulation project can work wonders from VB Insulation. Yet, you may encounter some hiccups. This guide helps you tackle common problems. It aims to make your project smoother.

Dealing with Overspray

Overspray often happens when you're using spray foam. It can go beyond where you initially aim it. Use good coverings for your floors and walls. Also, keep in mind how far the foam can expand.

If overspray occurs, act fast. Clean it with the products the spray foam company suggests.

Addressing Uneven Application

Getting a smooth, level application of spray foam is key. This ensures your home or building stays warm and sealed. If you spot areas that need more or less foam, don't worry. You can spray those spots again to level it out.

Follow the manufacturer's tips for a uniform application and follow their advice on spraying to get even coverage.

Cost-Effective Insulation Solutions with Spray Foam

We at VB Insulation know how vital it is to find cost-effective insulation. It should boost your home's efficiency and save you money in the long run. DIY spray foam insulation stands out for its impressive results at a reasonable cost.

Calculating Insulation Costs

Finding the money to insulate your home can take a lot of work initially. However, our insulation cost calculator helps you see what a DIY spray foam project might cost. It considers your project's size, the spray foam type, and other details, then breaks down your expenses.

Our cost-effective insulation solutions ensure better energy use without hurting your wallet. Our Vega Bond V600 kits are easy to use, making home improvements simple for homeowners. This means you can upgrade your home with confidence.

Long-Term Energy Savings

Spray foam insulation's greatest benefit is saving you money over time. It acts as a powerful barrier against air and heat loss, reducing your home's energy use and cutting your heating and cooling bills.

Choosing our energy-efficient renovations with spray foam does more than lower costs. It makes your home more comfortable and eco-friendly. Investing in these cost-effective insulation solutions promises a more energy-smart home for the future.

Conclusion

DIY spray foam insulation from VB Insulation is a great choice. It helps homeowners make their homes more energy efficient, comfortable, and perform better. By using the step-by-step guide and the needed safety precautions, you'll find it easy to do your insulation project. You can then enjoy a more energy-efficient and comfy home for years.

This guide is perfect if you want to boost your home's thermal performance, seal the air, or control moisture. It gives you the information and confidence to start a successful DIY home improvement project. By choosing eco-friendly insulation and sustainable building materials, you help make your home more energy efficient. Plus, you do your part for a greener world.

Ready to start? Begin your DIY home insulation project with VB Insulation's detailed guide. It allows you to enjoy the many benefits of making your home more energy efficient. Transform where you live into a cozy, cost-effective, and sustainable spot. Trust in DIY and begin your home improvement project, knowing you're well-prepared.

FAQ

What are the benefits of spray foam insulation?

Spray foam insulation is top-notch at sealing air, keeping out moisture, and insulating. It upgrades a home's energy efficiency, snips heating and cooling bills, and enhances comfort.

What types of spray foam insulation are available for DIY projects?

For DIY, open-cell and closed-cell types are available. They both have unique upsides. Choosing the right one depends on your needs and project.

What tools and equipment are required for a DIY spray foam insulation project?

For the DIY, you'll need a kit with spray foam, an applicator, and safety gear. Also, grab tools like a drill, putty knife, and tape measure. Don't forget your safety gear—goggles, gloves, and a mask.

How do I calculate the required R-value and insulation materials for my project?

Finding the right R-value and insulation takes into account the weather, building type, and local codes. Use an online calculator and chat with an expert. They'll guide you on the needed spray foam.

What are the key steps for properly applying spray foam insulation?

To start:

- Prep the surface by sealing any cracks.

- Mix the spray foam according to the instructions.

- Spray it on using the right tools and methods.

What safety precautions should I take when working with spray foam insulation?

Staying safe is crucial with spray foam. Always wear your protective gear, ensure good airflow, and follow the manufacturer's advice on safe use.

How can I troubleshoot common issues with DIY spray foam insulation?

If you face overspray or want it to be more even, techniques like masking and adjusting the spray can help. Watch how you apply it closely.

How can I maximize the cost-effectiveness of my DIY spray foam insulation project?

For a cost-effective DIY, plan your insulation and R-values carefully. Take advantage of any rebates. Consider how it'll cut your energy bills in the long run.