Did you know that there are various types of spray foam guns available on the market? From disposable options for small-scale projects to professional-grade guns for larger applications, the world of spray foam applicators is vast and diverse. Whether you are a DIY enthusiast or a professional contractor, understanding the different types of spray foam guns is crucial for achieving optimal results in your insulation projects.

Key Takeaways:

- There are different types of spray foam guns available on the market.

- Disposable spray foam guns are an affordable and convenient option for small projects.

- Professional-grade spray foam guns are necessary for larger insulation projects.

- Choosing the right spray foam gun depends on the project scale, budget, and specific requirements.

- This guide will provide valuable insights and recommendations to help you select the perfect spray foam gun for your needs.

Understanding Spray Foam Gun Basics

Before we explore the different types of spray foam guns available on the market, let's take a look at the basics. Understanding how these guns work and knowing the key features, components, and considerations when using them can help you make informed decisions for your insulation projects. We will also discuss the various types of spray foam equipment commonly used in conjunction with the guns to ensure optimal performance.

Key Features and Components

Spray foam guns are designed to spray foam. They have a pressure regulator, a temperature gauge, and a mixing chamber. These components work together to ensure a consistent and high-quality application of foam insulation.

One of the key features of spray foam guns is their ability to mix and apply two chemical components, namely polyol and isocyanate. These components react when they come into contact with each other, resulting in the expansion and hardening of the foam insulation. The mixing chamber in the spray foam gun ensures that these components are properly mixed in the correct ratio, ensuring the effectiveness of the insulation.

Another important feature of spray foam guns is the pressure regulator. This component allows the operator to control the pressure of the foam being sprayed. By adjusting the pressure, the operator can achieve the desired thickness and coverage of the foam insulation. It also helps in preventing overspray and waste of materials.

A temperature gauge is another component that ensures the proper application of foam insulation. It allows the operator to monitor the temperature of the chemicals as they are being sprayed. This is crucial, as the reaction between the components is temperature-dependent. Having a temperature gauge helps maintain the correct temperature range for optimal foam expansion and curing.

Spray foam insulation is known for its high insulating properties, energy efficiency, and comfort for building occupants. By using high-quality products, such as spray foam guns, it becomes possible to achieve a seamless and effective application of foam insulation. These key features and components play a vital role in ensuring the quality and effectiveness of the insulation, providing long-lasting thermal comfort for any structure.

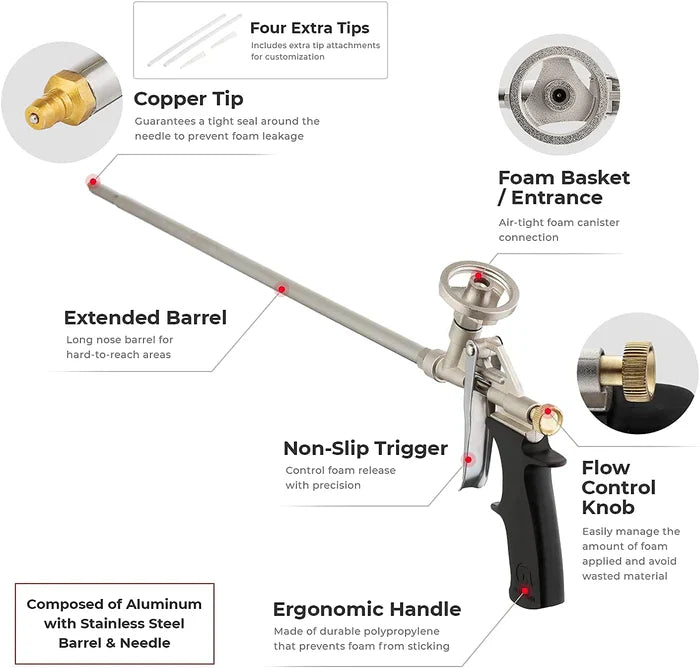

polyurethane foam insulation. They consist of several essential components:

- Spray Nozzle: The nozzle determines the size and shape of the foam spray pattern.

- Trigger: The trigger controls the flow of the foam and serves as an on/off switch.

- Regulator: The regulator allows you to control the pressure at which the foam is applied.

- Mixing Chamber: This is where the two liquid components of the foam mix and react to create the expanding foam insulation.

- Hose: The hose connects the spray gun to the foam supply.

- Cartridge: Some spray foam guns use disposable cartridges that contain the foam ingredients.

Spray Foam Equipment Types

In addition to spray foam guns, there are various types of equipment used in combination to achieve optimal insulation results. These include:

- Compressor: Provides the necessary air pressure to enable the spray foam gun to operate.

- Pump: Delivers the two liquid components of the foam to the spray gun.

- Heated Hose: Keeps the foam components at the ideal temperature for proper mixing and application.

- Protective Gear: Personal protective equipment such as gloves, goggles, and respiratory masks is essential for safety during spray foam application.

Our Top Accessories:

By understanding the basics of spray foam guns and the equipment used in conjunction with them, you can make informed decisions when it comes to selecting the right tools for your insulation projects. In the next sections, we will explore the specific types of spray foam guns, their advantages, and recommended applications.

|

Spray Foam Gun Type |

Advantages |

Recommended Applications |

|

Standard Spray Foam Gun |

Cost-effective and versatile |

Small to medium-sized insulation projects |

|

Low-Pressure Spray Foam Gun |

Provides precise control and reduces overspray. |

Detailed and intricate insulation applications |

|

High-Pressure Spray Foam Gun |

Efficient for large-scale insulation projects |

Commercial and industrial insulation applications |

Disposable spray foam guns

When it comes to small insulation projects, disposable spray foam guns offer a convenient and cost-effective solution. These single-use spray foam guns are designed to be used once and then disposed of, eliminating the need for cleaning and maintenance.

One of the key advantages of disposable spray foam guns is their simplicity. They are easy to use and require no additional tools or equipment. With a disposable spray foam gun, you can start your insulation project right away without having to worry about setup or prep time.

Another benefit of disposable spray foam guns is their affordability. Since they are designed for one-time use, they are generally more budget-friendly compared to reusable guns. This makes them ideal for small-scale projects or occasional use.

Disposable spray foam guns also provide a hygienic solution for insulation projects. With a new gun for each project, you can ensure a clean and uncontaminated application, minimizing the risk of cross-contamination or unwanted chemical reactions.

It is important to note that disposable spray foam guns do have limitations. Due to their single-use nature, they may not be suitable for larger or more complex insulation projects. Additionally, some disposable guns may have a shorter shelf life, so it is crucial to check the expiration date before use.

Advantages of Disposable Spray Foam Guns:

- Convenient and easy to use

- An affordable option for small projects

- A hygienic solution with a clean application

|

Advantages |

Limitations |

|

Convenient and easy to use |

Not suitable for larger projects |

|

An affordable option for small projects |

Shorter shelf life |

|

A hygienic solution with a clean application |

|

For small-scale insulation projects, disposable spray foam guns provide a practical and efficient solution. However, for larger or more complex projects, it may be worth considering other options. In the next section, we will explore professional-grade spray foam guns, which are designed for high performance and durability.

Professional-grade spray foam guns

For larger insulation projects or professional applications, the use of high-quality spray foam guns is paramount. These professional-grade spray foam guns offer numerous benefits, providing superior performance and efficiency compared to their lower-grade counterparts.

Benefits of Professional Guns

- Enhanced Durability: Professional-grade spray foam guns are built to withstand the demands of frequent use and heavy-duty applications. Their robust construction ensures durability and longevity, allowing them to withstand the rigors of professional use without compromising performance.

- Consistent Performance: High-quality spray foam guns deliver consistent and precise spray patterns, ensuring uniform application of the foam insulation. This results in a more even insulation layer, reducing the likelihood of gaps or uneven coverage.

- Efficient Material Usage: Professional-grade spray foam guns are designed to optimize material usage, minimizing wastage and maximizing the coverage per unit of foam. This efficiency not only saves on material costs but also reduces the overall project time.

- Ergonomic Design: Many professional spray foam guns are engineered with ergonomics in mind, offering enhanced comfort and reduced fatigue during long hours of use. This ergonomic design contributes to improved productivity and user satisfaction.

- Versatility: Professional spray foam guns often come with adjustable settings, allowing users to tailor the spray pattern and flow rate to meet the specific requirements of different projects. This versatility ensures optimal results across a wide range of insulation applications.

When choosing a professional-grade spray foam gun, it's important to consider several factors, such as the type of insulation material being used, the project scale, the desired spray pattern, and the available budget. By carefully assessing these factors and selecting a high-quality spray foam gun, professionals can expect superior results and increased efficiency in their insulation projects.

Conclusion

When it comes to insulation projects, choosing the right spray foam gun is essential. By understanding the different types of spray foam guns available on the market and considering factors such as project scale, budget, and specific requirements, you can make an informed decision and achieve optimal results.

In this guide, we have explored the various types of spray foam guns, from disposable options to professional-grade equipment. Disposable spray foam guns offer convenience and cost-effectiveness for smaller projects, while professional-grade guns are essential for larger or more professional applications.

By comparing the advantages and limitations of each type of spray foam gun, you can determine which one is best suited to your needs. Whether you choose a disposable or professional-grade gun, make sure to consider factors such as ease of use, durability, and compatibility with your chosen spray foam insulation product.

We hope this comprehensive guide has provided you with valuable insights and recommendations to help you select the perfect spray foam gun for your insulation projects. Remember to prioritize safety and always follow the manufacturer's instructions for optimal performance. Happy spraying!

FAQ

What are the different types of spray foam guns?

The different types of spray foam guns include disposable spray foam guns and professional-grade spray foam guns. Disposable spray foam guns are single-use and ideal for small insulation projects. Professional-grade spray foam guns are high-quality and designed for larger or professional applications.

What are the types of spray foam applicators?

Spray foam applicators can be categorized into two main types: disposable spray foam guns and professional-grade spray foam guns. Disposable spray foam guns are single-use and convenient for small projects, while professional-grade spray foam guns are high-quality and designed for larger or more professional applications.

How do I choose the right spray foam gun?

To choose the right spray foam gun, consider factors such as project scale, budget, and specific requirements. If you have a small insulation project, a disposable spray foam gun may be sufficient. For larger projects or professional use, invest in a high-quality, professional-grade spray foam gun.

What are the advantages of disposable spray foam guns?

Disposable spray foam guns offer convenience and cost-effectiveness, especially for small insulation projects. They eliminate the need for cleaning between uses and reduce the risk of clogging. Disposable spray foam guns are also easy to use and require minimal maintenance.

What are the benefits of professional-grade spray foam guns?

Professional-grade spray foam guns are designed for larger or professional applications and offer enhanced durability, performance, and precision. They have adjustable controls for spray patterns and flow rates, allowing for fine-tuning during insulation projects. Professional-grade spray foam guns also typically come with a longer warranty and may have additional features, such as anti-drip mechanisms.